- Forging

Forging is a manufacturing process in which external forces are applied to a workpiece, causing it to undergo plastic deformation. This results in changes to its size, shape, and improvement in mechanical properties. Forging is widely used in the production of machine parts, components, and raw materials. The forging process includes both forging proper and stamping operations.

- Hot Forging

Hot forging is carried out at a temperature above the recrystallization temperature of the metal. At such elevated temperatures, the metal exhibits enhanced plasticity, allowing for easier deformation and reduction of the required forging force.

- Warm Forging

Warm forging is conducted within a temperature range that is higher than room temperature but lower than the recrystallization temperature of the metal. This process combines some advantages of both cold and hot forging, such as better dimensional accuracy compared to hot forging and lower force requirements compared to cold forging.

- Isothermal Forging

Isothermal forging is a specialized forging method where the temperature remains constant throughout the entire forging process. To achieve this, both the forging die and the workpiece are heated to the required forging temperature. This ensures uniform deformation of the material and is often used for materials that are sensitive to temperature variations during forging.

- Cold Forging

Cold forging is performed at room temperature. Common cold forging processes include cold extrusion, cold heading, and cold pressing. Cold forging can produce parts with high dimensional accuracy and good surface finish, as well as improve the mechanical properties of the material through work hardening.

- Die Forging

Die forging is a process in which a die is used to shape a billet into a desired forging. The die contains a cavity that conforms to the shape of the final part, and the billet is deformed within this cavity under the application of pressure.

- Open-Die Forging

In open-die forging, the gap between the two dies is perpendicular to the direction of die movement. During the forging process, this gap gradually decreases as the workpiece is deformed. Open-die forging is suitable for producing large, simple-shaped forgings and is often used in the initial stages of shaping large ingots.

- Closed-Die Forging

Closed-die forging, also known as closed-impression forging, involves a die setup where the gap between the two dies is parallel to the die movement direction, and this gap size remains constant throughout the forging process. The workpiece is completely enclosed within the die cavity, resulting in a more precise and complex shape compared to open-die forging.

- Multi-Directional Forging

Multi-directional forging is a technique where loading is applied simultaneously in multiple directions. This process is carried out within a closed die with multiple sub-faces. It is particularly useful for manufacturing components such as valve bodies, which require minimal subsequent machining due to the high precision achieved during forging.

- Precision Forging

Precision forging is a forging method that yields forgings with high dimensional accuracy. Parts produced by precision forging often require little to no additional machining, making it an efficient and cost-effective manufacturing process for components with tight tolerances.

- Closed-Impression Forging

In closed-impression forging, the die cavity is pre-formed to match the external contour of the forging. A punch is then forced into the closed die to fill the cavity, shaping the part and creating holes if required. This process ensures accurate replication of the desired part shape and is commonly used for producing complex-shaped forgings.

- High-Speed Forging

High-speed forging is a processing method that uses high-velocity air or nitrogen to drive a slider along with the die for forging or extrusion operations. The high-speed impact of the die on the workpiece allows for rapid deformation and is suitable for high-volume production of certain forging products.

- Composite Forging

Composite forging combines different forging processes, such as hot forging, warm forging, and cold forging. By integrating these processes, it is possible to take advantage of the unique benefits of each method and produce parts with optimized properties and quality.

- Forging Grain Flow

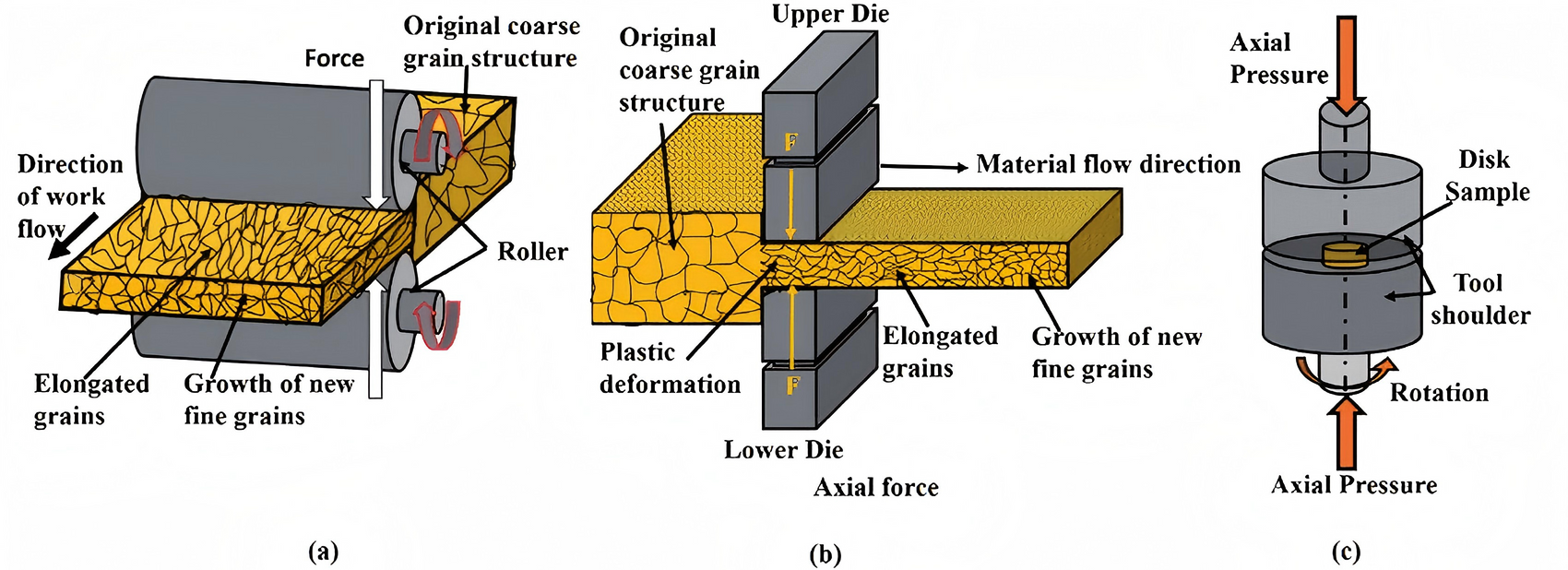

During the forging process, brittle metal impurities are fragmented, and plastic impurities align along the primary direction of elongation. This alignment of impurities and the resulting directional arrangement of the metal's microstructure is called forging grain flow. Forging grain flow imparts anisotropic properties to the forged part, meaning its mechanical properties vary depending on the direction of testing.

- Forging Ratio

The forging ratio is a measure of the degree of deformation during forging. It is typically expressed as the ratio of cross-sectional areas, lengths, or heights of the workpiece before and after deformation. The forging ratio is an important parameter in controlling the quality and mechanical properties of the forged product.

- Blanking

Blanking is a stamping process that uses shearing forces to separate a shaped component or blank from a larger sheet of material. This process is commonly used to produce various flat parts with specific shapes and dimensions.

- Punching

Punching is a stamping operation in which material within a blank is removed along a closed contour to create perforated parts. The removed material is considered waste, and the resulting part has holes of the desired shape and size.

- Cutting

Cutting involves dividing a blank into separate parts or making partial cuts, either internally or externally. This can be achieved through various methods such as shearing, sawing, or laser cutting, depending on the material and the required precision.

- Deformation

Under the pressure of a mold, a blank undergoes changes in shape and size without separation to obtain stamped parts of specific shapes and sizes. Deformation processes include bending, deep drawing, flanging, bulging, expanding, contracting, twisting, undulating, embossing, and coining.

- Bending

Bending is a process in which flat sheets, profiles, or pipes are shaped into components with specific curvatures and angles under the application of bending moments. This can be achieved using various bending tools and methods, depending on the material and the complexity of the bend.

- Deep Drawing

Deep drawing uses rigid dies to apply tensile or compressive stresses to a blank, transforming flat blanks into cylindrical, conical, or other complex shapes, with or without flanges. During the deep drawing process, the thickness of the material remains nearly constant.

- Flanging

Flanging is the process of creating upright edges along certain curves on the flat or curved edges of a blank. This can be used to strengthen the edges of a part, create attachment points, or improve the aesthetic appearance.

- Bulging

Bulging involves applying bidirectional tensile stresses to flat sheets or hollow blanks to induce plastic deformation and obtain the desired shape. This process is often used to create components with expanded sections or unique contours.

- Expanding and Contracting

Expanding and contracting are processes where dies are used to apply force to hollow blanks, tubular blanks, or hollow parts to achieve an increase or decrease in diameter at the ends. These processes are commonly used in the manufacturing of pipes, fittings, and containers.

- Twisting

Twisting is the process of applying a torque to a stamped part to rotate it to a specific angle, creating components with twisted shapes. This can be used in the production of shafts, screws, and other parts with helical features.

- Embossing

Embossing is the process of creating various raised and recessed patterns or shapes on the surface of blanks or finished products by locally reducing the thickness of the material. This technique is often used for decorative purposes or to improve the grip or functionality of a part.